Description:

Nonwoven fabric coated with PES Single dot

On T/C and 100% cotton fabric have best performance.

| Item No. | Com. | Weight (gsm) | Coating method | Color | Width(cm) | ||

| Fabric | Coating | ||||||

| DR-146WE | 100%PET | 14 | 4 PES | Single dot | White/Off white | 90/100/150 | |

| DR-166CE | 100%PET | 16 | 4 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

| DR-166BE | 100%PET | 16 | 4 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

| DR-186WE | 100%PET | 18 | 7 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

| ND-186WE | 50%nylon | 18 | 7 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

| DR-256WE | 100%PET | 25 | 10 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

| DF-256WE | 100%PET | 25 | 10 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

| DR-324WE | 100%PET | 32 | 10 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

| DR-324CE | 100%PET | 32 | 10 PES | Single dot | White/Charcoal/Black | 90/100/150 | |

Fusing Condition:

| Temperature ( ℃ ) | Time ( S ) | Pressure ( N/cm2 ) |

| 130-145 | 12-14 | 1.5-2.5 |

Wash, Iron, Instruction:

The above settings are our standard recommendations.

We recommend that fusing trials and subsequent care treatment are carried out before production commences.

TECHICAL DATA SHEET FOR

Nylon and Polyester mixed thermal bonding fabric with PES or PA coating

Description:

Nylon mixed thermal bonding nonwoven with PES & PA coating Doudble dot .

Siliconized thermal bonded nonwoven with PES or PA coating for siliconized and water proof fabric

Widely Compatible, On Cotton, VT, T/C and T 100% have best performance.

| Item No. | Com. | Weight (gsm) | Coating method | Color | Width(cm) | ||

| Fabric | Coating | ||||||

| ND-186OE | 50%nylon | 18 | 7 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-186WE | 50%nylon | 18 | 7 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-256CA | 50%nylon | 25 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-256BA | 50%nylon | 25 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-274WE | 50%nylon | 27 | 9 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-274CE | 50%nylon | 27 | 9 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-304WA | 50%nylon | 30 | 12 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-304BA | 50%nylon | 30 | 12 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| OND-206OA | 50%nylon | 20 | 8 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| OND-206BA | 50%nylon | 20 | 8 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

Fusing Condition:

| Temperature ( ℃ ) | Time ( S ) | Pressure ( N/cm2 ) |

| 130-145 | 12-14 | 1.5-2.5 |

Wash, Iron, Instruction:

The above settings are our standard recommendations.

We recommend that fusing trials and subsequent care treatment are carried out before production commences.

TECHICAL DATA SHEET for

100% Polyester thermal bonding fabric with PES coating Double dot

Description:

Nonwoven fabric made by 100% PET, coated with PES Double dot

Widely compatible. On Cotton, VT, T/C and T 100% fabric have best performance.

| Item No. | Com. | Weight (gsm) | Coating method | Color | Width(cm) | ||

| Fabric | Coating | ||||||

| SR-146WE | 100%PET | 14 | 5 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-176OE | 100%PET | 17 | 6 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-186WE | 100%PET | 18 | 7 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-206WE | 100%PET | 20 | 8 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-206CE | 100%PET | 20 | 8 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-256WE | 100%PET | 25 | 9 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-256CE | 100%PET | 25 | 9 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-274WE | 100%PET | 27 | 9 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-314WE | 100%PET | 31 | 12 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-344CE | 100%PET | 34 | 11 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-454BE | 100%PET | 45 | 13 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SF-554CE | 100%PET | 55 | 14 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-654WE | 100%PET | 65 | 15 PES | Double dot | White/Charcoal/Black | 90/100/150 | |

Fusing Condition:

| Temperature ( ℃ ) | Time ( S ) | Pressure ( N/cm2 ) |

| 130-145 | 12-14 | 1.5-2.5 |

Wash, Iron, Dry Instruction:

The above settings are our standard recommendations.

We recommend that fusing trials and subsequent care treatment are carried out before production commences.

TECHICAL DATA SHEET FOR

100% Polyester thermal bonding fabric with PA coating

General Description:

Nonwoven fabric made by 100% PET, coated with PA.

Widely compatible. On Cotton, VT, T/C and T 100% fabric have best performance.

| Item No. | Com. | Weight (gsm) | Coating method | Color | Width(cm) | ||

| Fabric | Coating | ||||||

| SR-186WA | 100%PET | 18 | 7 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| ND-186WA | 50%nylon | 18 | 7 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-226WA | 100%PET | 22 | 8 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| SF-256WA | 100%PET | 25 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| SF-256CA | 100%PET | 25 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-286WA | 100%PET | 28 | 12 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-324WA | 100%PET | 32 | 13 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| FX-254OA | 100%PET | 32 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| FX-254WA | 100%PET | 32 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| FX-254CA | 100%PET | 32 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| FX-254BA | 100%PET | 32 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-186WAA | 100%PET | 18 | 6 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

| SR-256WAA | 100%PET | 25 | 10 PA | Double dot | White/Charcoal/Black | 90/100/150 | |

Fusing Condition:

| Temperature ( ℃ ) | Time ( S ) | Pressure ( N/cm2 ) |

| 130-145 | 12-14 | 1.5-2.5 |

Wash, Iron, Dry Instruction:

The above settings are our standard recommendations.

We recommend that fusing trials and subsequent care treatment are carried out before production commences.

Applications

Related Articles

-

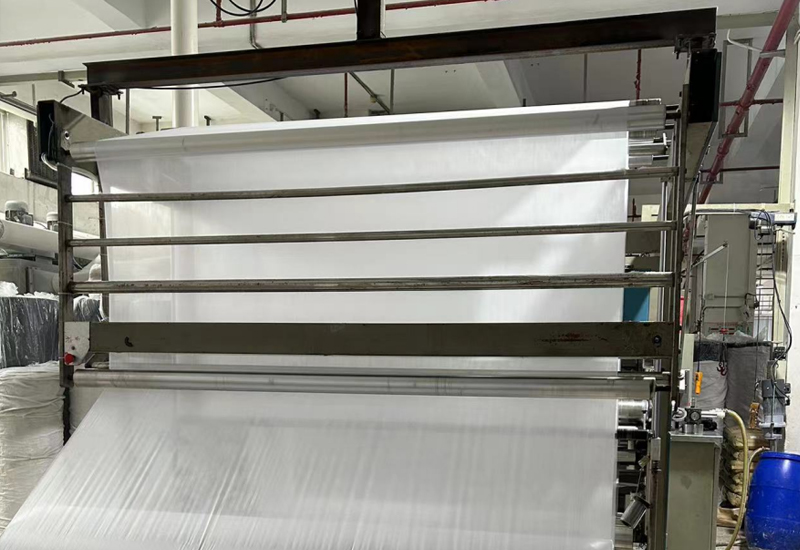

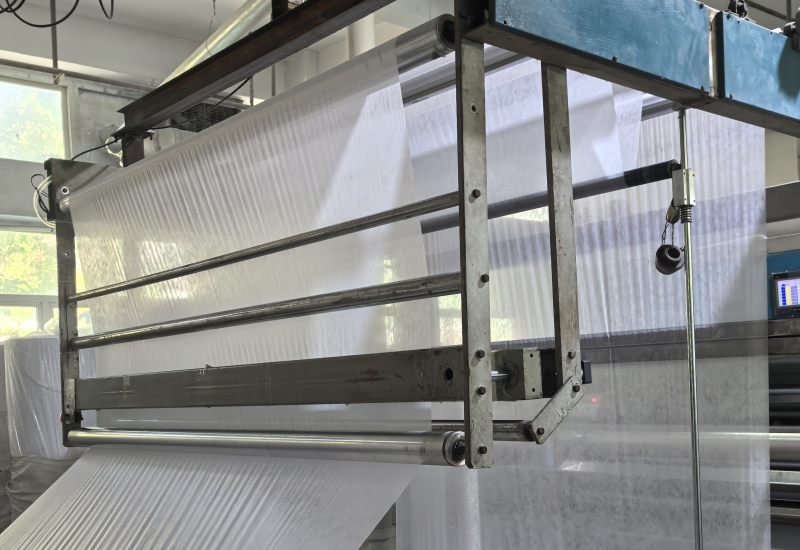

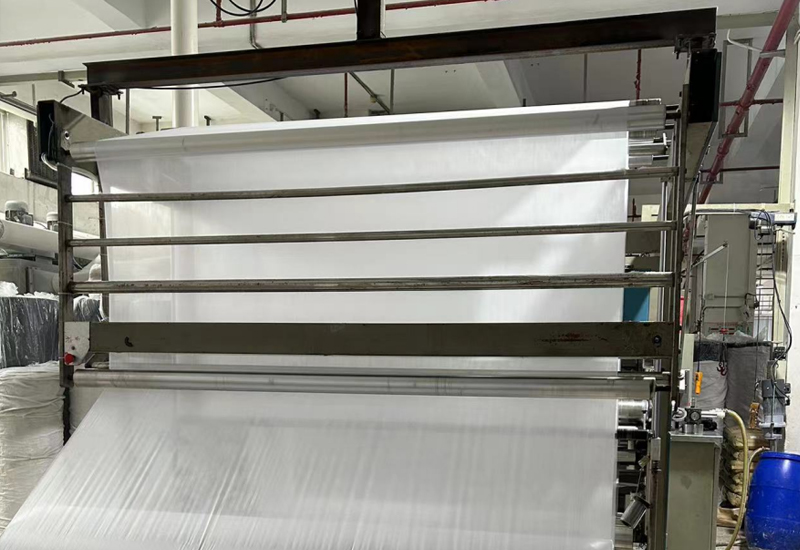

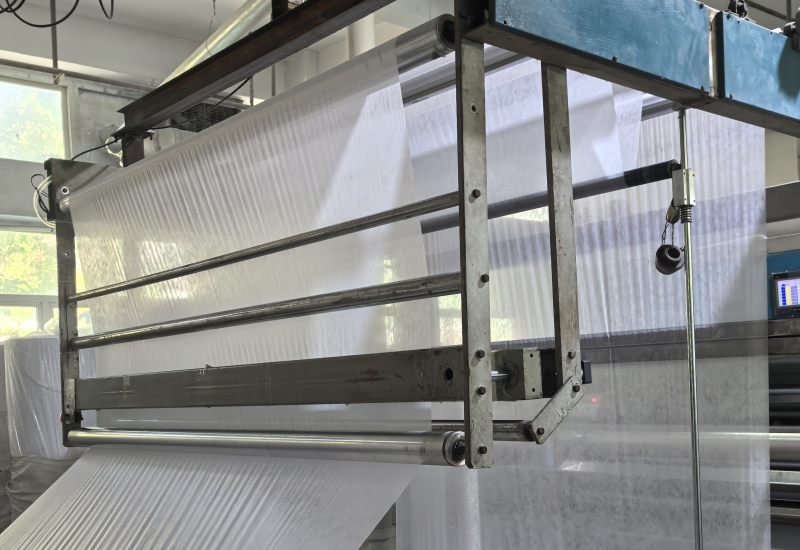

1- Establishment and Initial Production (2008)The company was founded in Huadu District, Guangzhou in 2008. It established the first double-dot coating line and powder-dot line, with a monthly output of 5 million meters.2- Relocation and Capacity Expansion (2022)Facing the complex market environment

1- Establishment and Initial Production (2008)The company was founded in Huadu District, Guangzhou in 2008. It established the first double-dot coating line and powder-dot line, with a monthly output of 5 million meters.2- Relocation and Capacity Expansion (2022)Facing the complex market environment -

1- Establishment and Initial Production (2008)The company was founded in Huadu District, Guangzhou in 2008. It established the first double-dot coating line and powder-dot line, with a monthly output of 5 million meters.2- Relocation and Capacity Expansion (2022)Facing the complex market environment

1- Establishment and Initial Production (2008)The company was founded in Huadu District, Guangzhou in 2008. It established the first double-dot coating line and powder-dot line, with a monthly output of 5 million meters.2- Relocation and Capacity Expansion (2022)Facing the complex market environment -

1- Establishment and Initial Production (2008)The company was founded in Huadu District, Guangzhou in 2008. It established the first double-dot coating line and powder-dot line, with a monthly output of 5 million meters.2- Relocation and Capacity Expansion (2022)Facing the complex market environment

1- Establishment and Initial Production (2008)The company was founded in Huadu District, Guangzhou in 2008. It established the first double-dot coating line and powder-dot line, with a monthly output of 5 million meters.2- Relocation and Capacity Expansion (2022)Facing the complex market environment